WF-Plastic’s innovative systems provide maximum protection for hot-runner systems, which are integrated into plastic processing machines (injection, extrusion, and blowing). The systems are effective in preventing leakages of hot plastic during the injection process.

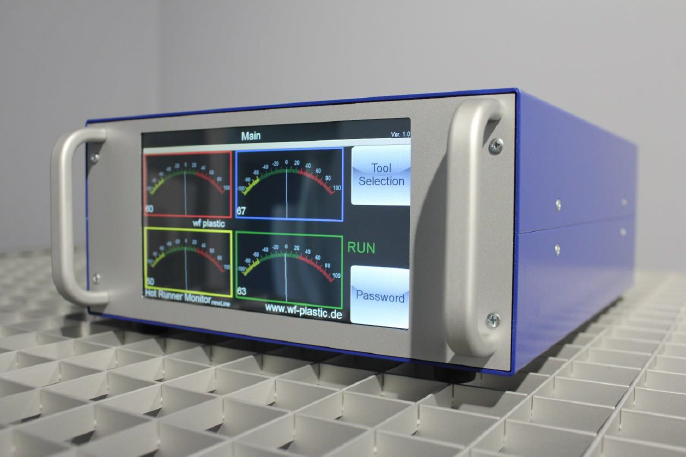

The Nozzle Melt Monitor (NMM) and the Hot Runner Monitor (HRM) meet international standards and have proven themselves in the plastic industry for more than 15 years.

The systems interface through OPC-UA. The system monitor is installed inside the machine’s control panel cabinet, or alternatively is placed as a satellite unit on the machine. Connection to the system is also possible via the HRMAPP dedicated app, by smartphone or PAD.

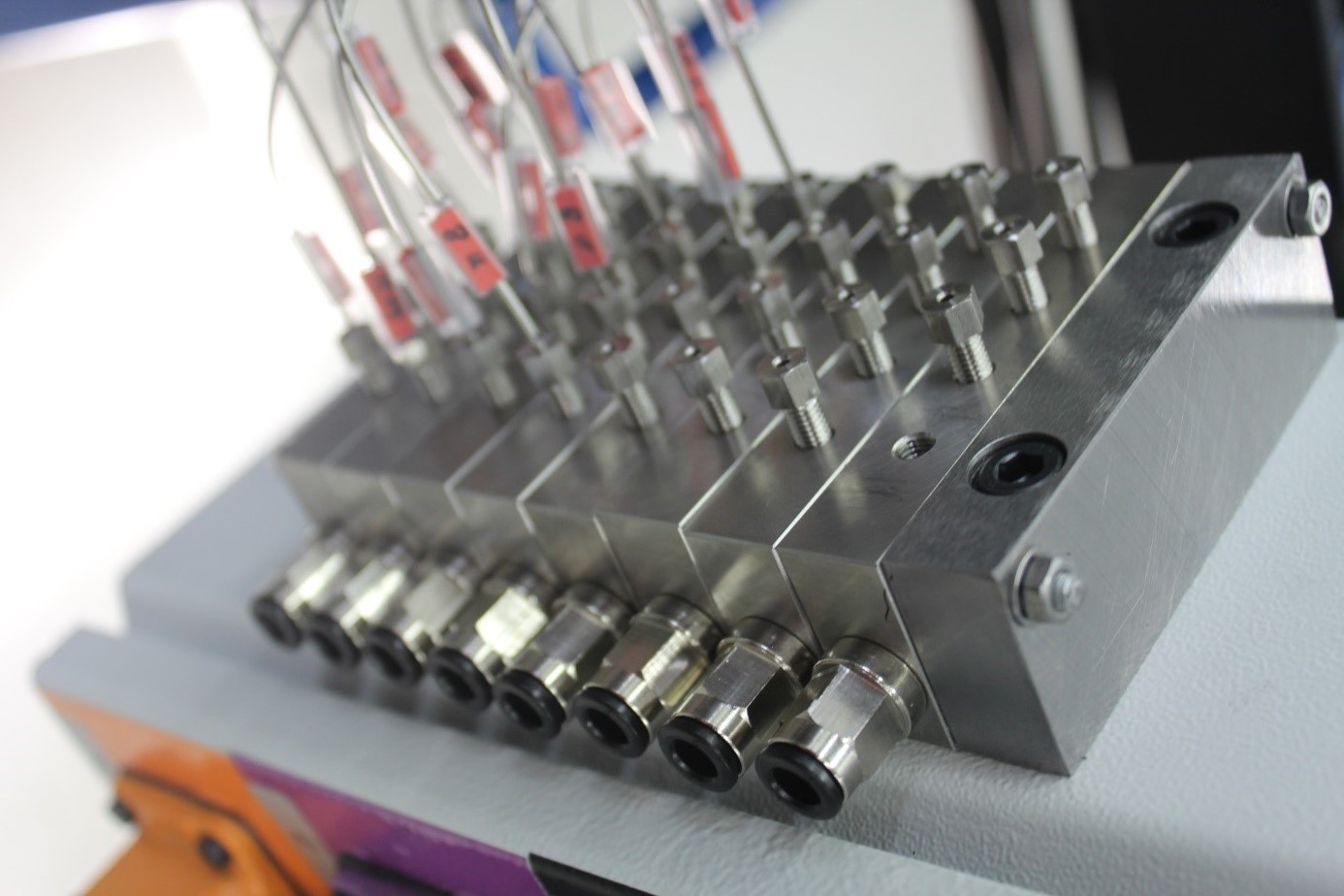

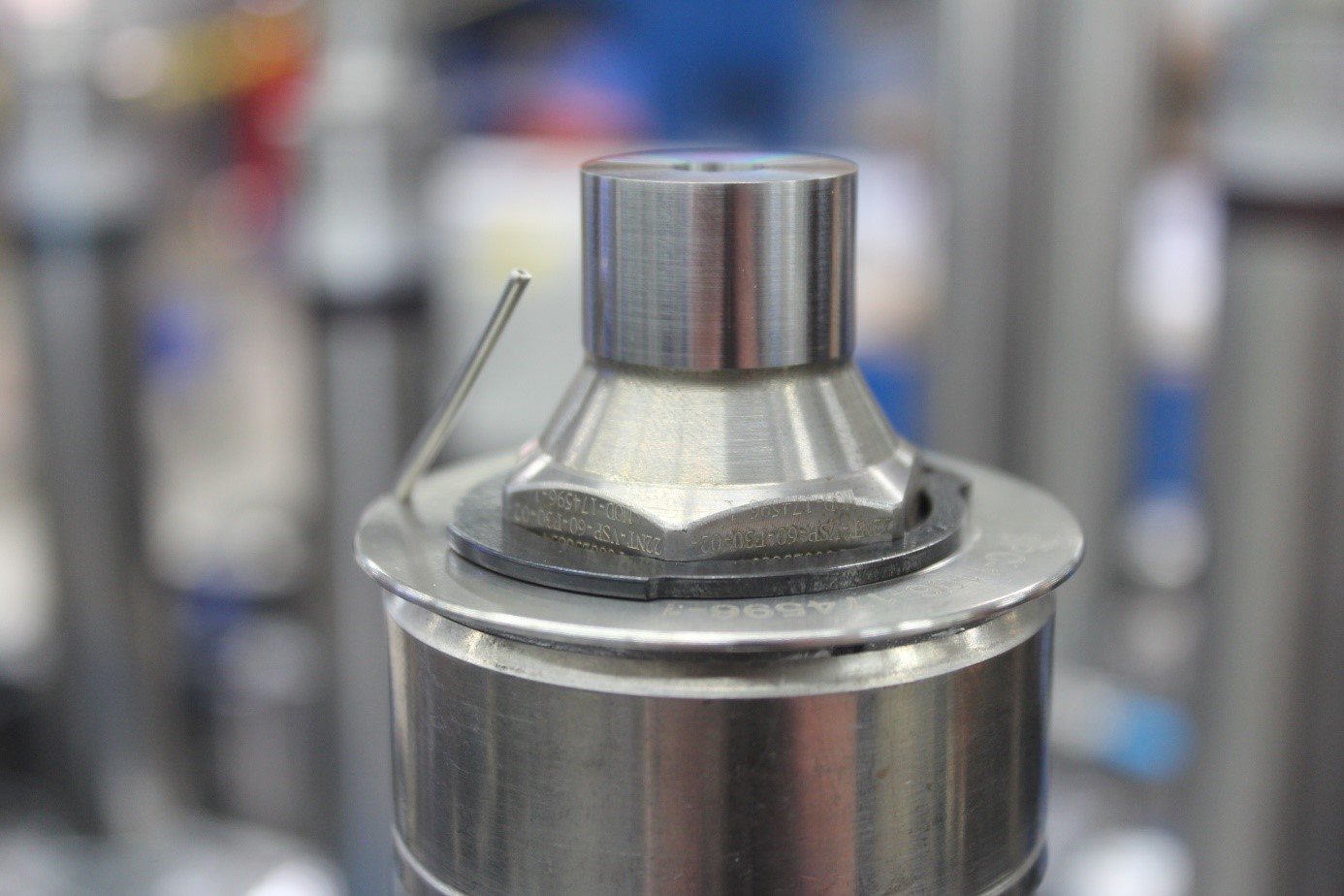

Instruction video for the installation of the HRM on a hot runner system: